Cleanroom Design

A. CRITERIA FOR EVALUATION OF CLEAN ROOM DESIGN

AIR PURIFICATION SYSTEM

In the process of clean room design it is necessary to pay attention to the selection and installation of the air purification system. At present, the air purification system mainly has two types, layer flow and turbulent flow, which need to be selected according to the needs of the clean room, but also depends on the overall environmental parameter situation.

EVALUATE THE LAYOUT OF PEOPLE AND MATERIALS

In a manufacturing plant employee are the most important source of cleanroom contamination, so not only their mobility but also the tools and materials they carry must be assessed during the design of the room. clean. For this purpose, a plan of the directions in which people move in the environment and the routes in which they travel is prepared in order to initially have a plan.

CLEAN LEVEL DURING CONSTRUCTION

It is important to know what environment people will be working in and how clean they will be. There are several standards for classifying cleanrooms. The common denominator of all of them is that this is based on the amount of contamination per unit volume. So each of these standards has one thing in common. The classification helps a lot with the design, construction, then maintenance and repair, so the class of the room must be specified.

AIR PRESSURE

Air in the room is very important, because even a simple breeze can carry a lot of particles. The air pressure in the controlled space is usually lower than in other components, and this causes the air to move towards this part. Calculating the air pressure allows great care when designing equipment and components involved in controlling air pressure differentials and maintaining the desired level.

DETERMINE THE FLOW OF AIR

The direction of the flow is important for grading air cleanliness because it puts several elements out of your reach. For this purpose, classification is used in such a way that a specific standard is established based on the amount of change in the airflow per hour. This standard defines which class the room belongs to.

OUTFLOW AIRFLOW

If a cleanroom is separated from other components as standard, it will have positive pressure on the surroundings due to this separation, so the airflow tends to leave it. This air can escape from anywhere, even holes, so for a controlled environment, all parts of air outlet must be controlled.

AIR BALANCE DURING CLEAN ROOM CONSTRUCTION

Air-equilibrium means that negative or positive pressure produces no outflow or inflow into the space. As mentioned, air control is very important, so one of the most important steps in building a clean room is to test the difference between the dimensions of the air pressure.

B. CLEAN ROOM DESIGN DETAILS

SHOW THE FACTORY FLOOR PLAN

The first part we need to show is the factory floor plan. Let us see if the layout of the door and the way is reasonable. If there is a problem, we need to change it properly.

DESIGN DRAWING OF CEILING AND FLOOR SYSTEM

The second part is the ceiling and floor. This part is in the construction category, we need to clearly show what the clean room construction materials are. What is the ceiling height, what material is the ceiling used. Door type, size and opening direction of the door. All are clearly shown and noted in the drawings and attached to the detail.

For clean room wall and ceiling items, it is often required to use antistatic panel materials with a thickness of 50 to 150mm depending on each project. This helps to ensure the maximum reduction of the ability to charge electricity into the electrical components of the production cabinet. In addition, for some factories with high output requirements, other methods are also used.

Commonly used clean room floors are vinyl floors or anti-static epoxy painted floors. Clean rooms with high class will use anti-static raised floors to both ensure cleanliness and ensure the anti-static ability of the clean room.

CLEAN ROOM VENTILATION DESIGN DRAWINGS

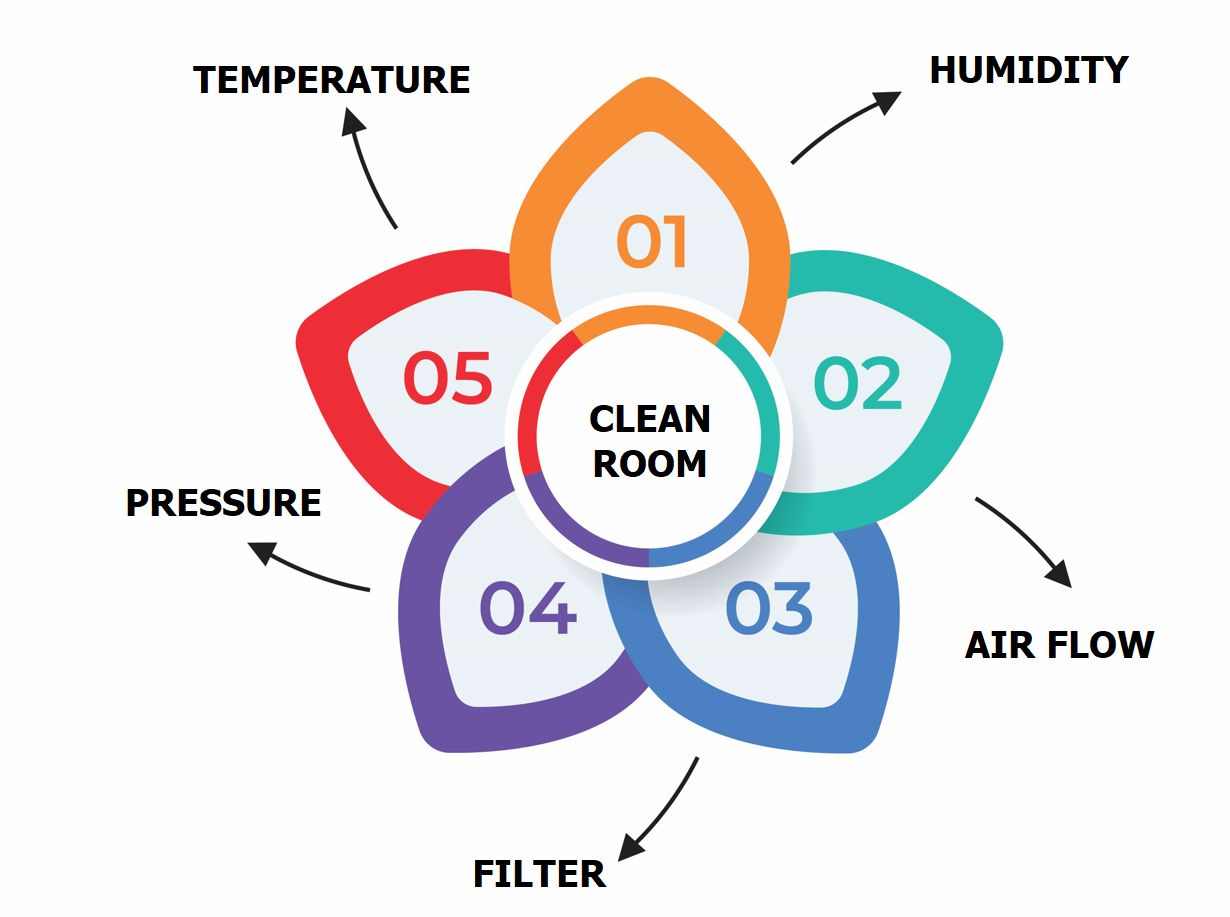

The ventilation system in the clean room should be clearly shown in the required areas. Such as temperature, humidity, pressure and wind principle. We should split the parts into different drawings. It should not be confused and the drawing should clearly show the content to be presented.The ventilation system in the clean room is extremely important. Because it directly affects factors such as temperature, humidity, pressure, cleanliness level, etc.

The commonly used ventilation equipment such as: AHU, Chiller, BFU, FFU, Hepa …

Each device will have a different role in the overall space of the clean room

CLEAN ROOM ELECTRICAL DESIGN DRAWING

As well as other categories. Each item we need to show its main content. In the electrical section there are the following sections:

Clean room electrical control system.

+ Each different type of electronic component has a different production environment requirement. However, in general, this environment must be controlled in terms of temperature and humidity in the allowed spread. Currently, there are two control methods commonly used in Vietnam:

+ Control by PLC

+ Central control BMS

Electrodynamic system

In the clean room electrical system, it is divided into two main electrical systems as follows:

+ Electric light system.

+ Power system.

+ Electric lighting system.

+ Power system for production machines.

+ Power supply system for other devices.

+ Power supply system.

DESIGN DRAWINGS OF CLEANROOM AUXILIARY SYSTEMS

In addition to the above specific items, there are ancillary systems for clean rooms, such as:

+ Water supply system: Demineralized water, RO filtered water, purified water, injection water, loop system.

+ Gas supply system: Nitrogen, CO2, vacuum, compressed air, EO gas, LPG gas…

+ Hot water and steam system: Boiler, steam production, pure steam, water for injection.

+ Drainage system.

+ Waste water treatment system.

+ Fire protection system